Visit our new shop on line site for current pricing and products. www.RiggingAndHardware.com

JIB FURLING GEAR

POLES

MAIN SAIL FURLING and REEFING

REEFING and LazyJacks

MAIN SAIL TRACK SYSTEMS

STANDING RIGGING

SWAGE TERMINALS and toggles

INNER FORESTAY TOOLS AND MISC HARDWARE

LIFE LINES

RUNNING RIGGING

BLOCKS

WINCHES

ANTAL

TRAVELERS

BOOM VANGS

RIGID VANGS

GROUND TACKLE

WINDLASSES

MAST CLIMBING

tools, lubes steering

tools, lubes and steering

RADAR MOUNTS AND REFLECTORS

Service has always been the core of our business. It enables us to help you select and install the appropriate gear on your boat.

We maintain complete in house and on site service capability. Our service trucks run from Rhode Island through Cape Cod on a regular basis. Our two water front service locations, quality of service, and fair pricing have attracted boats from as far away as the Chesapeake Bay area for hands on service. We have spar hauling capacity to 100'+. There are 60 ton and 350 ton travel lifts on site to haul boats up to 150'. We service 12 yards in the Buzzards Bay area plus many private individuals on a continual basis. Most manufacturers have told us we are the largest roller furling service center in the country. We are frequently used as a resource for product development and design evaluation by a number of them for many different types of rigging products. Settling disputes between insurance companies, yards, manufacturers, and private individuals at their request we believe is a statement of our respect and integrity.

|

STANDING RIGGING |

| Many of our competitors send your work to a contractor or a separate location to be made. At RIGGING ONLY your rigging stays right here. This insures that your rig meets our standards, allows instant status checks, improves turn around time, and most important keeps quality at it's peak. Standing rigging is not just some wire with a fitting on each end. With the changes in the wire and fittings industries, geographic peculiarities, the varied uses of each boat, and the economics of the pleasure boat business you really need to talk to experienced people. | |

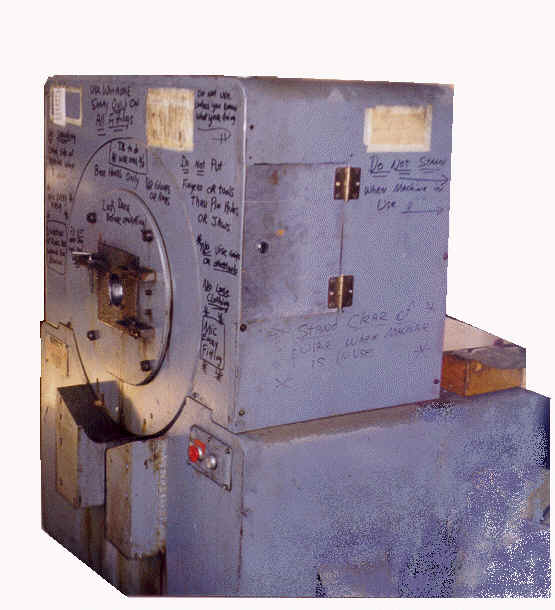

| Rotary swaging

allows us to control metal flow into the wire stranding by .002". It

also eliminates the lines created on the fittings by roller style dies.

Rotary swaging starts where the wire enters the fitting and compresses the

fitting onto the wire stretching the fitting away from the wire.

Roller swaging starts at the head of the fitting and stretches the fitting

down over the wire making for more contact with the wire.

There are two basic forms of roller swaging. One uses powered dies

where the die pushes (or rolls) the fitting thru two dies that are made to

military specs compressing the fitting onto the wire. Most commonly

used machine is called a "Kearney" and can be seen in a lot of small shops.

The problems with the Kearney machine is they are not built strong enough to

roll larger diameter wires in one pass and require multiple passes to reach

specifications for the fittings and the fitting guide is often not used

properly and is not long enough to accommodate larger fittings. Due to

gear lash (play in the gears) the dies often don't make contact with the

fitting at exactly the same time and cause the fitting shank to curve

(banana) making for improper strain on the wire. A second type of

power roller machine called a Top Reef is now available that does away with

most of the problems of the Kearney. We are using on of these for

smaller diameter wire and have been pleased with the results. Casings

are much stronger along with the drive hubs and the gearing is made with

German precision.

A third type of roller machine (Wire Techniques) pulls the fitting

thru two dies making for a very straight and perfect swage. We are

using this type of machine on most of our large diameter wire (7/16 and up).

We offer all three types of swaging. If you have a preference let us

know. Every swage fitting is measured with a micrometer to insure compliance with strict US. military specifications. All Norseman and Sta-Lok fittings are assembled using the highest quality and freshest sealant and thread lock available. All wire is type 316 from 7/32 on up. Smaller wire may be type 304 depending on the application. All wire terminations are type 316 stainless. Wire splicing for traditional rigging is done in house. We splice 7xs, 1x19, and any other construction that is splicable. We do work for a number of museums. We sell and splice all types of line. Selection of the line we sell is based on a manufacture's consistency of product, application, and longevity. There are many different qualities of similar types of line on the market. Lower quality may be acceptable to some, but over the long haul will end up costing more. Line made to custom sizes and specifications is available. Our wire to rope splices are all double spliced onto tapered wire (the old fashioned way) We've pull tested them at 110% of the wire breaking strength. We do both braid to wire and three strand to wire. Our line splicing is as strong as it comes. We were called on by the J Class boats when a competitors splices failed to hold. We'll help you select the appropriate line. We are not interested in selling you the most high tec line for your application, just the right line for you.

|

|